Ultimate Guide To Tile Adhesive Mortar

What is tile adhesive mortar?

Tile adhesive mortar is a cement-based mortar used for installing tiles, usually by mixing cement with lime, fine sand, additives and other auxiliary materials. Due to its high strength, 10-15MPa, good cohesive force, excellent impact and pressure resistance, as well as good water resistance and durability, it is extremely durable.

Tile adhesive mortar has a PH value of 10 which is a highly alkaline substance. It does not contain harmful substances and is safe to use for human health and the environment. Its low water absorption can effectively prevent the penetration of moisture into the mortar.

Its good physical and chemical properties, which can firmly bond the tiles on the building surface to prevent the tiles from falling off or moving; it maintains the beauty and decorative effect of the building surface for a long period of time, which reduces maintenance and frequency of replacement, widely used in building materials.

tile adhesive mortar applications

The main purpose of tile adhesive mortar is to fix and install ceramic tiles, ceramic tiles or stone. It is primarily used in the following applications:

Installation of floors: for indoor and outdoor applications, including living rooms, kitchens, bathrooms, balconies, and gardens.

Decoration of walls: used in kitchens, bathrooms, washrooms, porches, and other areas.

Pools and spas: used for the interior and exterior finishing of swimming pools and spas.

Commercial buildings: This material is widely used in commercial buildings, such as office buildings, shopping centers, hotels, restaurants, etc.

How to use tile adhesive mortar?

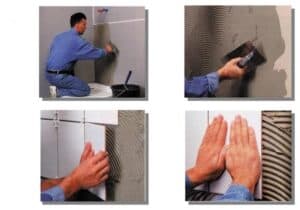

Follow these steps when using tile adhesive mortar:

Make sure the base is flat, dry, clean, and that any existing oil, dust, or old mortar has been removed.

Using the directions on the package, mix the appropriate amount of tile bonding mortar with water and mix thoroughly until a homogeneous slurry is obtained.

Use a scraper or a trowel to apply the mixed mortar to the base in order to form a thin back film.

In order to ensure that tiles are closely attached to the base, comb the tile bonding mortar in a specific direction and push it flat with one side of the scraper.

The tiles should be placed on the mortared base and lightly pressed to bond with the mortar.

Clean up any excess mortar before it dries to avoid difficult removal.

The mortar should be dried and cured according to the instructions provided by the mortar. It usually takes a few days for the mortar to be completely dry and cured.

Before using tile bonding mortar, it is recommended that you read and follow the manufacturer’s instructions and safety guidelines.

How tile adhesive mortar is manufactured?

Fine sand is first dried by an energy-saving and efficient drum dryer until it reaches a moisture content of at least 1% before it is mixed with cement, lime, fine sand, adhesive, and other raw materials. Upon storing the raw materials in a closed silo, they are conveyed to the weighing and batching system by screw conveyors; the specific proportions of these materials are then transported to the twin-shaft mixer through the bucket elevator for uniform mixing.

To ensure quality and stability of mixing during the mixing process, the fully automated intelligent PLC control cabinet and monitoring equipment can be used to monitor and view the time, speed, dose accuracy, and other parameters of the conveying and mixing process. The finished product is packaged and stacked through the intelligent packing-palletizing system after stirring for approximately one to two minutes.

Using the 100% intelligent production line, users are able to save labor costs, realize a faster and more efficient production method, as well as ensure the accuracy of raw material ratios and the stability of tile bonding mortars.

Benefit working with Dura Mortar

In order to achieve a seamless and aesthetically pleasing finish, our bonding mortars have been carefully formulated to be compatible with a variety of grouts and sealants. It has excellent resistance to environmental elements such as humidity, temperature changes and shocks, ensuring your tiles remain secure in place for years to come.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"