What Is Decorative Mortar?

Decorative mortar is applied over surfaces like walls, floors, or ceilings to enhance their appearance, texture, or color.

What is the decorative mortar ?

Decorative mortar is a material commonly used in architectural decoration, which originated from the pursuit of architectural aesthetics by ancient humans and the need to protect architectural structures.

Its high strength and durability, as well as its super plasticity and weather resistance, make decorative mortar ideal for decorating walls, ceilings and other architectural elements, while also resisting weathering, ultraviolet radiation, temperature changes in the natural environment Erosion from factors such as humidity and moisture, thereby maintaining long-term aesthetics and functionality.

Decorative mortar can not only be used to create various colors, textures and patterns to make buildings more beautiful and attractive, but also can prevent damage from moisture penetration, ultraviolet radiation and chemical pollutants, while it is easy to clean and maintain the building because of the smooth finish.

Decorative Mortar Applications

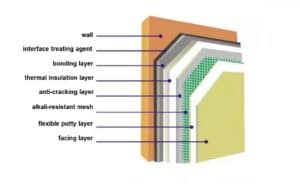

Decorative mortar can be applied on the surface of the inner and outer walls of the building, and the lower and middle layers are basically the same as ordinary plastering mortar. For the decorative surface layer, it is necessary to select cementitious materials and aggregates with a certain color and to adopt some special operating techniques to make the surface present decorative effects such as different colors, lines and patterns.

The cementitious materials used in decorative mortar are ordinary cement, white cement and colored cement, as well as lime and gypsum. Aggregate is often made of marble, granite and other colored gravel slag or glass and ceramic granules. White or colored natural sand, special plastic colored particles, etc. can also be used.

Commonly craft-usage of decoration mortar:

(1) Brushed wall coating

On the middle layer of cement mortar or cement mixed mortar plastering, spread cement mixed mortar, paper lime or cement lime slurry, etc., and use a pulling tool to pull out the corrugated and spotted hairs of the mortar to make a decorative surface layer. It is generally suitable for indoor walls such as auditoriums and theaters with acoustic requirements, and is also commonly used for exterior walls, balcony railings or enclosures.

(2) Water brush stone coating

Use the mortar mixed with fine-grained gravel (about 5mm) as the surface layer. After the surface is slightly solidified, immediately spray water to wash the surface cement slurry, so that the gravel is half exposed. Water brushed stone is mostly used for exterior wall decoration of buildings. It has the texture of natural stone and is durable.

(3) Dry sticky stone coating

It is to stick the colored stone particles directly on the mortar layer. Compared with water brushing stone, this method not only saves raw materials such as cement and stone particles, but also reduces wet work and improves work efficiency.

(4) Cut fake stone coating

Also known as chopping stone, it is to smear cement stone slurry on the cement mortar base, and after hardening, chop out regular stone patterns with tools such as chopping axe, toothed ax and various chisels, so that it can form natural granite roughness. crazy effect. It is mainly used for decoration on outdoor cylinders, pins, railings, steps, etc.

(5) Elastic coating

Elastic coating is to brush a layer of polymer cement mortar on the surface of the wall, and use a bullet applicator to bounce polymer cement mortar of different colors on the painted base layer several times to form 3-5mm oblate flower spots. Spray mask with methyl silicone. It is suitable for interior and exterior walls of buildings, and can also be used for ceiling finishes.

(6) Spraying coating

Spraying is mostly used for exterior walls. It uses extrusion mortar pumps or spray hoppers to spray polymer cement mortar on the wall base or low ash to form a finish layer, and finally spray a layer of methyl silanol on the surface. Sodium or methyl silicone hydrophobizing agents to improve finish durability and reduce wall staining.

Decorative mortar production process

The production process of decorative mortar usually includes the steps of raw material preparation, mixing, processing and packaging.

1) Raw material preparation: Gypsum, cement, pigments, fillers and other raw materials are stored in silos and transported by conveyors;

2) Stirring: Add the pre-prepared raw materials into the mixing equipment according to a specific ratio, and use a mixer or a mixing tank to mix thoroughly to ensure that the raw materials are evenly dispersed.

3) Processing: The mixed mortar needs further processing, such as removing impurities, adjusting viscosity, etc.These processing steps can be accomplished using equipment such as screens, filters, regulating valves, etc.

4) Packaging: The decorative mortar needs to be packaged by a packaging machine for storage and transportation. Common packaging methods include bags, barrels or cans.

It should be noted that the specific production process and equipment used may vary with different types of decorative mortar. The above is the general production process and common equipment. In the actual production process, it can be adjusted and optimized according to specific needs.

Features of decorative mortar :

- Effectively absorb deformation stress and prevent surface cracks;

- Better strength, temperature stability and durability;

- Perfect balance of water resistance and breathability;

- Suitable for the intermediate coating of various decorative and protective coatings for exterior walls of buildings. It has the functions of waterproof, anti-cracking, and pattern.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"