one-click start sand making production line manufacturer

Welcome to Dura Mortar, your one-stop destination for high-quality and reliable sand making production line manufacturer. Our production line is designed to provide a seamless and hassle-free experience, making it easy for you to get started with your production process.

Featured Clients

Efficient and Reliable Sand Making Production Line for High-Quality Sand and Gravel Materials

Sand Drying Production Line

Sand Making Production Line

Thermoplastic Road Marking Paint Production Line

Tile Adhesive Production Line

Raymond Mill Production Line

Thermal Insulation Mortar Production Line

Client Review

The sand just needs to be packaged with a packaging machine. The high friction and fluidity of the sand makes the packaging results of several specifications of the packaging machine not satisfactory; Sunny from Dura Mortar recommended the ultrasonic air blowing packaging machine, which uses pneumatic power to push the sand into the bag, so it's smooth and durable! Thanks Sunny!

Sand Production Line Related Machineries

In addition to sand making production line equipment, Dura Morta also provides ultrasonic packaging machines, combustion machines, and screw conveyors.

Air flotation valve packaging machine:

Packing powder products with air flotation valve packaging machines is a common sealing process. The packaging bag is opened by an air flow at the valve opening, then is fully opened and fixed, then sealed. It works like that.

Burner:

Burners burn fuel (diesel/natural gas/biomass fuel/coal, etc.). They are widely used in industrial fields, including power plants, boilers, kilns, dryers, and industrial heating equipment.

Screw conveyor:

Chemicals, building materials, metallurgy, grain, and other industries use screw conveyors as conveying equipment to move powder, granular, and small blocks. In addition to the spiral body, there’s a bearing, a transmission device, an inlet and an outlet, and a frame.

How to start your own sand making production line?

Here’s what you need to do to set up a sand making factory:

1) Market research: Identify target markets, competitors, potential customers, demand trends. Assess market potential.

2) Site and land: Find a good place to build the factory and get all the necessary permits and approvals.

3) Equipment and machines: buy or lease crushers, screening machines, sand washing machines, etc., for the sand production line.

4) Raw material supply: Make sure your raw material supply chain is stable, like stone, sand, cement, etc.

5) Staff training: recruiting and training operators, technicians, and managers.

6) Environmental protection and safety: Make sure the factory is operating according to relevant standards by complying with environmental regulations.

7) Quality control: Make sure products meet relevant standards and customer requirements with a quality control system.

8) Capital and budget: Plan factory construction, equipment purchases, salaries, raw material procurement, marketing, and other expenses, and come up with a reasonable investment budget.

The specific investment amount depends on multiple factors, like factory size, equipment selection, and regional cost differences. Dura Mortar can help you figure it out.

What's a systematic and comprehensive sand production line like?

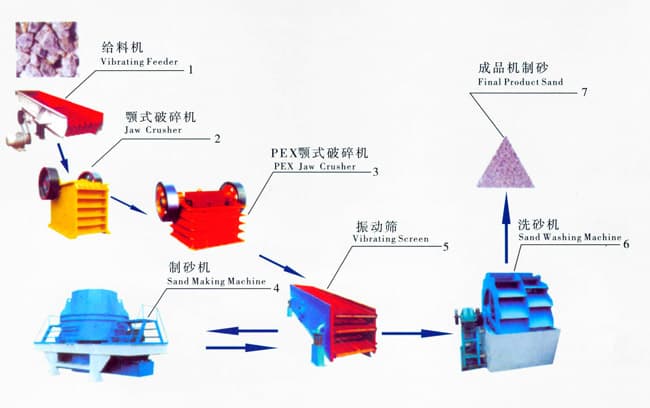

There are usually a few steps to a systematic sand making production line operation:

1) Raw material processing: Stones and ores are preliminarily cleaned to remove impurities like soil and impurities to maintain quality and specifications.

(2) Crushing: After raw material treatment, it’s time to crush the raw material into sand-making size. Jaw crushers and impact crushers can do it.

3) Screening: The raw materials need to be screened after crushing to separate stones of different specs. Circular vibrating screens and linear vibrating screens can be used for screening.

4) Clean up: After sieving, the raw materials need to be washed to remove soil and impurities. Sand washing machines can do it.

5) Sand and gravel preparation: After washing, raw materials are sent to sand making equipment for sand making, such as sand making machines and hammer crushers.

6) Sand and gravel storage: the sand and gravel materials are stored in silos, hoppers, and other storage equipment.

7) Dust control: When the sand making line operates, a lot of dust gets generated, which needs to be dealt with with dust control equipment to keep workers and the environment safe. Wet dust removal equipment, dust collectors, and other dust control equipment are among the dust control items.

Various equipment in the sand production line needs to be maintained and maintained regularly to ensure normal operation and extend their lives.

How Dura Mortar offers you reliable sand making production line solution

We need to understand the raw material characteristics before designing the sand production line for you so we can determine the right crushing equipment and screening equipment for you. We can determine what kind of crushing, screening, washing, and other equipment to use for your production line based on its capacity. Choose the right equipment based on your production capacity and process requirements.

Communicate with suppliers to find suitable equipment options based on factors like performance, efficiency, and maintenance costs.

Automated systems can increase production efficiency, reduce labor costs, and ensure stable operation. Decide what level of automation you need based on your production line’s size and automation requirements.

To ensure that the production line conforms to relevant safety standards and environmental protection regulations, we will also consider safety and environmental protection factors during the design process.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"