Dry Mix Mortar Production Project In Kosowo

Introduction

Client's Challenge

Client's Technical Challenge

Dura Mortar's Solution:

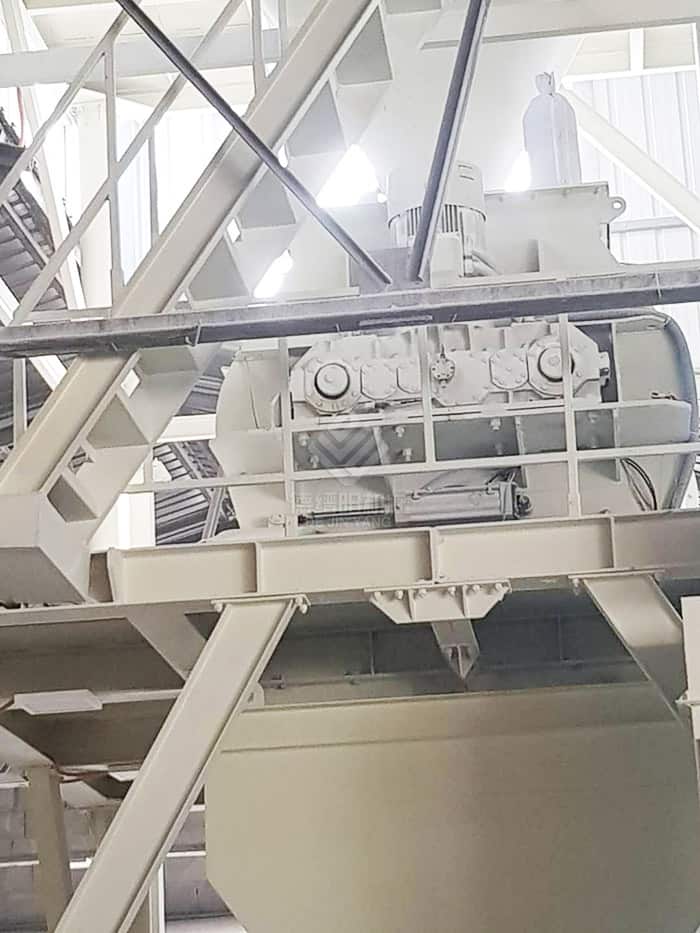

We have confirmed all the needs of customers through multiple video conferences, telephone communications etc., and combined with the customer’s site conditions and plant heights, and designed the entire process from transportation-storage-ingredients-mixing-packaging-palletizing for customers. A set of fully automatic production line equipment, while meeting the output, pay more attention to the intelligent production line to reduce labor management costs and losses.

Results:

Our solution solves all the concerns and needs of customers. This intelligent production line can reduce the failure rate for customers by 10-15%; although the final total price exceeds 25% of the customer’s budget, the customer confirmed the solution within a week Just sign the contract and pay 50% deposit.

Sincerely thanks to all the staff of Dura Mortar for designing a time-saving and labor-saving intelligent mortar production line for us. We are very happy! The professional attitude, efficient service and perfect design of Dura Mortar and Ms. Sunny made our purchasing and using experience very good!