Ultimate guide to Thermal insulation mortar

What is the thermal insulation mortar ?

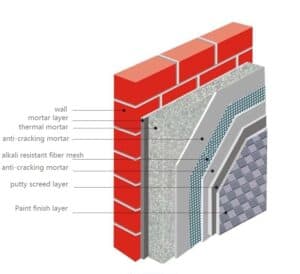

Generally, thermal insulation mortar is used to reduce heat transfer from walls, roofs, and other surfaces, either externally or internally.

Its excellent insulating properties help limit heat flow through the mortar. Heat passing through coated surfaces can be reduced by using insulating materials with low thermal conductivity; insulating mortars are usually light in weight, so they help to reduce the overall weight of building structures; in addition, they are fire resistant, which contributes to the overall safety of the building as a whole.

Buildings can be made more energy efficient by reducing heat transfer through walls and roofs with insulation mortars. By maintaining a comfortable indoor temperature, reducing the need for excessive heating and cooling, and reducing energy consumption and associated costs, it contributes to maintaining a comfortable indoor environment. Besides insulating the building envelope, it can minimize temperature fluctuations and drafts, resulting in an indoor environment that is more stable and comfortable.

The application of thermal insulation mortar

1.

An insulation mortar is a material used for building insulation, and it is used in a wide range of applications, including:

Wall insulation: Insulation mortar can be used as part of the insulation layer on the external walls of a building to provide excellent thermal insulation as well as reduce heat loss.

Roofing Insulation: Insulation mortar can be applied to the insulation layer of the roofing structure to act as a heat insulation and to reduce heat transfer and energy consumption.

Insulation of the floor: In floor insulation systems, insulating mortar can be used to seal the gap between the ground layer and the insulation layer, thereby providing additional insulation and preventing heat transfer.

Insulation for pipes: This involves wrapping the pipes in an effort to prevent energy loss. Insulation mortar can be used to form a uniform layer of insulation around the pipes, providing effective heat insulation.

Cold Storage Insulation:

Thermal insulation mortar can be used on the walls, roof, and ground of cold storage facilities to provide good thermal insulation performance.

It is usually necessary to mix thermal insulation mortar with an appropriate amount of water in order to form a uniform paste when using it. The insulating mortar must then be applied, sprayed, or filled onto the desired surfaces, ensuring that it covers the entire area evenly. In addition, the insulating mortar should be cured and dried according to the manufacturer’s instructions.

Please note that specific construction specifications and operating steps may apply in certain construction applications. Before using thermal insulation mortar, please read and follow the relevant instructions and guidance carefully.

Thermal Insulation Mortar Production Process

To produce thermal insulation mortar, you will need specific equipment and machinery.

Raw material preparation:

1) Cement: Cement silo, cement crusher (if needed);

2) Fillers (such as expanded perlite, vermiculite, or lightweight aggregates): Silos for storing fillers;

3) Additives (such as water-reducing agents, air-entraining agents): Mixing tanks or dispensing systems;

4) Mixing and blending:

A batch mixer or continuous mixer can be a paddle mixer, ribbon blender, or high-speed mixer capable of homogeneous mixing, depending on the scale of production.

Water supply system: Tanks, pumps, and pipelines for precisely controlling the addition of water.

5) Packaging and storage:

*Packaging machine: Bagging machines or silo systems with automatic filling mechanisms for packaging the finished mortar.

*Storage area: Warehouse or silos for storing the packaged or bulk mortar.

6) Quality control:

Testing equipment: Instruments to measure properties like thermal conductivity, compressive strength, adhesion, density, etc. These may include devices such as thermal conductivity meters,

Get Started With Dura Mortar

If you want your home or office to reduce the heat consumption of the walls, waterproof and waterproof, and reduce maintenance costs; please choose duramotar thermal mortar.

Providing fully automatic thermal mortar production lines, one-stop procurement, turnkey projects and 24 hour online support, Dura Mortar offers one-on-one design, production, transportation, installation and training services. A Butler-style caring service will make your mortar production project more efficient, energy-efficient and hassle-free.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"