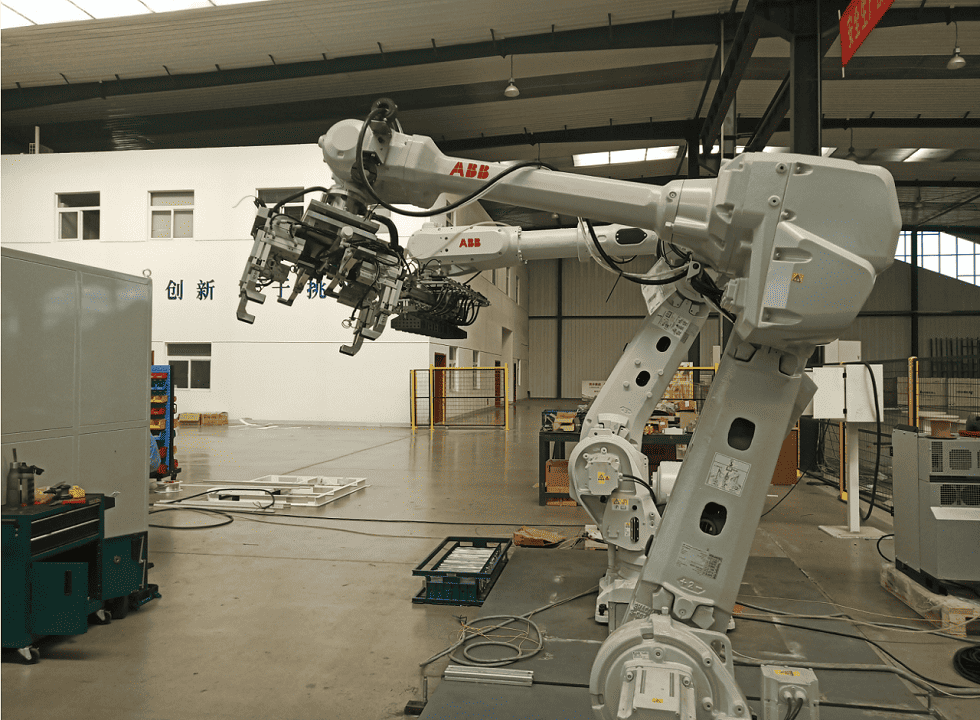

Robotic Palletzier Machine manufacturing

Robot palletizers are perfect for packing and palletizing finished products of all shapes, like cartons, bags, cans, boxes, bottles, etc. used in chemical, beverage, food, beer, plastic, air-conditioning, and other industries.

What Is Robotic palletizer Machine?

There is no need for a large space to accommodate the Robotic Palletizer; all controls can be operated through the control cabinet’s screen, and the operation is very straightforward. With its ability to work around the clock and equipped with robotic hands, it is capable of replacing many workers’ work, saving hundreds of thousands of dollars in human resource costs, reducing staff costs, and increasing efficiency.

Developed as the result of a combined effort between machinery and computer programs, the Robot Palletizier provides higher production efficiency for modern production. Palletizing machines are widely used in the palletizing industry. Using robotic palletiziers greatly reduces labor costs and saves space. Robot palletiziers are flexibly and accurately operable, quickly and efficiently, with high levels of stability and operational efficiency.

In addition to its flexible and compact installation space, the palletizing system incorporates patented coordinate robot technology. It has become possible to construct a fully automatic block making machine production line that is highly efficient and energy-efficient within a small footprint.

When the workpiece on the flat plate meets the pallet’s requirements, the flat plate and workpiece move forward until they reach the pallet’s vertical surface. When the upper stopper rod is lowered, the other three positioning stopper rods begin clamping, and the plate resets. Each workpiece is lowered to the plane of the pallet, with a distance of 10mm between the pallet and the bottom surface of the plate, and the pallet is lowered one workpiece height. Stack pallets in accordance with the set requirements by reciprocating the above steps. The Robotic palletizer is equipped with a special custom-designed multifunctional gripper, which can firmly grip and transfer the box using vacuum suction cups, regardless of the box’s size or weight.

Palletizing manipulators can also be utilized in combination with various dry powder mortar production lines, paint and thermoplastic marking paint production lines, and can lift, move, and rotate bagged mortars and 20 barreled paints through various fixtures, including forward tilt and rollover. Place it on the predefined tray and delivery position, including forward tilt and rollover.

The benefits brings by the Robotic palletizer

Automatic robot palletizers are developed in accordance with the advancement of robot technology. They can mimic the action functions of human hands and arms, grasp objects, transfer them, or manipulate them according to the established procedures. There are many applications for fully automatic palletizers, such as replacing human labor, automating production, operating in messy and hazardous environments, and protecting people from harmful and messy environments. As a result, manual palletizing must be replaced by automatic palletizers.

In order to meet the demands of large-scale production, deal with monotonous and repetitive labor, and improve production quality, fully automated palletizers have become one of the most important symbols of a country’s technological and manufacturing capability. The application of automatic palletizers is becoming increasingly and more extensive, the demand is also increasing, and the research and development of its technology are becoming increasingly detailed, which will improve the productivity and product quality of society, as well as create tremendous financial benefits for society as a whole.

From the generation to the development of the automatic robot palletizer, it has also generated enormous wealth for society from the perspective of energy conservation and environmental protection. The improvement of production efficiency, product quality, reduction of labor intensity, and improvement of working conditions have become a priority for enterprises following continuous improvement of production efficiency. Due to its ability to meet all of these conditions, it has become an increasingly ambitious enterprise since it was established as an automatic palletizer. This type of automatic palletizing machine not only enhances the competitiveness of enterprises, but also brings obvious benefits to users while also creating a great deal of wealth for society as a whole.

It saves a great deal of human resources and considerably improves the working environment by using automatic robot palletizers. Rather than employ repetitive manual labor, it employs mechanical active operation methods, which greatly improves the operating efficiency of the palletizer. People are naturally interested in fully automatic palletizers.

In addition to saving a significant amount of manual labor, palletizers also improve the working environment and reliability of people, and together improve everyone’s environment, save energy, protect the environment, and save the enterprise a great deal of capital. There are significant economic benefits associated with this process. Using automatic palletizers breaks the original traditional production mode and takes a new road to industrialization with a high technological content, good economic benefits, low resource consumption, and less pollution.

Daily maintences of Robotic palletizer

After the robot palletizing is in place, there’s no signal from the proximity switch. Three checks need to be done at this point. Make sure the proximity switch is far from the sensor board, make sure the wiring is loose, or make sure the proximity switch isn’t damaged. Then adjust the position, rewire, or replace the damaged parts according to the control structure.

Whenever the robot palletizer is in place, the photoelectric switch doesn’t work. It’s just that the inspection location is different. Next, make sure the photoelectric switch’s sending and receiving ends are aligned with the palletizing manipulator, and the reflective photoelectric switch is aligned with the reflector. In addition, it’s important to keep the distance between the direct photoelectricity and the detected object within a reasonable range. Any foreign matter blocking must be removed ASAP.

The upper magnetic ring switch of the robot palletizer doesn’t get a signal after the cylinder moves. This is because the magnetic ring switch position in the system isn’t right. To fix it, you need to move the magnetic ring switch so the light is on, then install it. The same thing happens if the cylinder rod doesn’t extend or retract, which can be fixed by adjusting the cylinder head gasket.

Robot palletizer automatic solenoid valve failure If the machine isn’t working, press the stop button on the control panel or on-site button box to make sure it’s stopped before continuing. To prevent false starts and make sure the fault control environment is stable, disconnect the power supply of the equipment when necessary.

Robotic palletizer by Dura Mortar

You can stack multiple production lines at once with our intelligent robot palletizer, which can perform high-precision operations and help you quickly palletize and depalletize.

It’s automated, and the perfect safety interlock makes it safe for the operators and equipment. Using intelligent robots is easy, so your production gets accelerated and efficient because they’re light on themselves.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"