sand making machine manufacturing

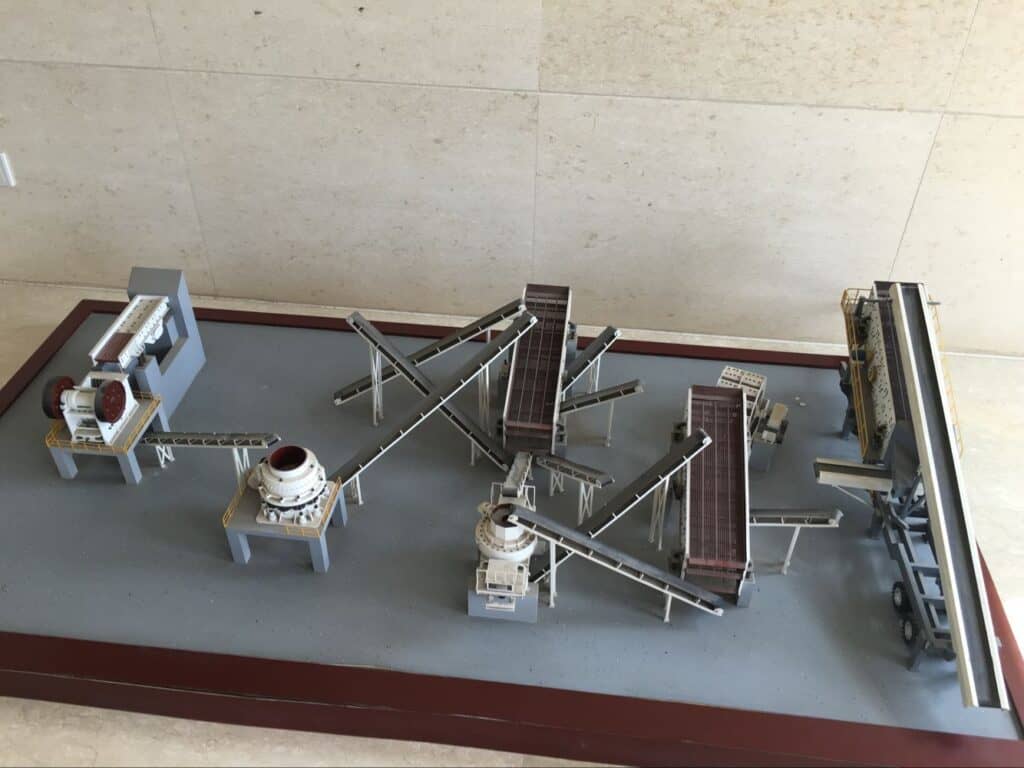

Typically, sand making machines produce artificial sand, which is widely used in the mining industry for processing and producing sand and gravel aggregates, such as for building materials, iron ore beneficiation, and metal ore smelting.

What Is sand making Machine?

Sand making machines make fine granular sand by crushing, crushing, and plasticizing raw materials (like rocks and ores).

Construction, roads, railways, bridges, water conservation, and chemical industries use sand making machines to make sand and gravel. This sand can be used for concrete mixing stations, asphalt production lines, railway track beds, and highway foundations. It’s also used for engineering projects like that.

This applies to the following production lines:

Construction engineering: Sand making machines are used in concrete, blocks, artificial stone, etc.

Rail and highway engineering: roads, roadbeds, and pavements.

Water conservancy projects: dams, hydropower stations, ports, etc.

Chemical industry: Sand making machines are used to make chemical raw materials, metallurgical ores, and refractory materials.

In general, sand making machines play a significant role in various engineering fields, providing high-quality sand for different production lines.

Material passing rate has increased by more than 30%, boosting production capacity!

Using Dura Mortar's sand making machine is super easy, and the material passing rate has gone up by 30%, so the production capacity is way up. Also, the fully sealed device makes it easy to prevent dust overflow, reduce pollution, basically no dust and noise, and makes green and environmentally friendly production. Great stuff!

Maintenance for sand makers

Sand making machine impeller maintenance

In maintaining a sandmaking machine, the impeller is one of the most important parts, and it’s also the most vulnerable.

When viewed from the feed port, make sure the impeller rotates counterclockwise.

If the particle assembly wears the impeller, the size of the feed should meet the requirements: the feed of the sand making machine should be uniform and continuous, and the raw material should be about 5 cm.

Whenever you shut down the sand maker, you should stop feeding first, otherwise it’s easy to damage the impeller.

Maintain normal operation by checking and replacing the impeller device regularly.

sand making machine rotor bearing maintenance

It’s important to choose the right type of rotor bearing. Most people use double-row radial spherical roller bearings.

Whenever the rotor bearing is working, it mainly takes the impact load, and the outer ring and bearing seat should be F8 or E8. The rolling element under the force line of the impact load is the most stressed, and the inner and outer ring raceways are also here. When it’s in contact with the rolling elements, it’s the strongest.

Add a rubber plate between the bearing seat and the support frame to make the bearing seat more flexible. 3. Improve the stress condition of the bearing. By increasing housing compliance, shock loads are reduced.

Keep an eye on the impeller, bearing, and other parts of your sand making machine. Maintenance of the sand making machine should pay more attention to its key components. As well as watching for blockages of materials entering the sand making machine, pay attention to how it works when it’s running.

Sand making machine working principle

By the time the material gets to the sand making machine, it gets divided into two parts by the distributor, and one part gets into the rotating impeller from the middle, and it gets accelerated there hundreds of times faster than gravity.

A part of the material that falls from the surrounding area of the distributor is impacted and crushed, and then the material lining in the vortex support cavity hits it together and gets crushed. The material is then thrown out at 60-70 m/s from the three evenly distributed runners of the impeller.

In the vortex crushing chamber, the material liner bounces, impacts obliquely upward, changes direction, deflects downward, and the material emitted by the impeller channel forms a continuous material curtain, crushing a piece of material. Crush materials with two or more chances at impact, friction, and grinding, and then they’re discharged at the bottom.

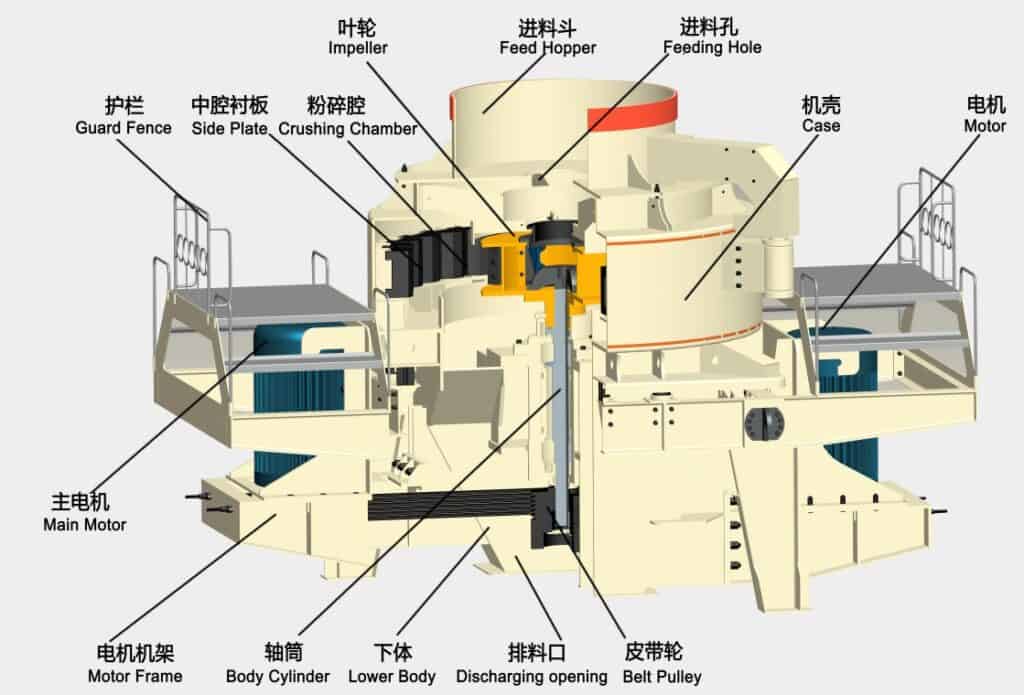

Structural features of sand making machine:

1. The main shaft assembly of the sand making machine is installed in the middle of the square prism

It transmits power from the motor through the V-belt and keeps the impeller rotating.

2. The impeller is installed on the shaft head at the upper end of the main shaft assembly. On the base are the vortex crushing cavity, the main shaft assembly, the motor, and the transmission. The base can be mounted directly on the foundation or on a bracket.

3. There are two kinds of transmission devices: single motor drive and double motor drive. The motors are installed on both sides of the main shaft assembly. V-belt pulleys are attached to the motor, so they balance the forces on both sides of the shaft but don’t create extra torque.

Sand making machine performance advantages:

Large throughput and high output: After analyzing and improving before the design, there’s no problem like frequent shutdown, sand blockage, and motor failure, so it not only simplifies production, but also increases throughput by 30% thanks to the deep cavity impeller design. It’s very efficient, so it makes a big difference in production.

Green and environmental protection: A fully sealed device prevents dust overflow. The materials collide and break by themselves during operation, so corner pollution is reduced. Moreover, it’s equipped with a dust collection and noise reduction device, so it doesn’t generate dust and noise, and it’s eco-friendly.

Cost reduction: It’s extremely smart, so it doesn’t require much work. It’s a stone crushing machine that makes sand and shapes it. One machine is multi-purpose, and it makes good sand. Sand reduces capital investment to a certain extent because it gives users finished products with a good grain shape and uniform size.

Unrestricted: You can also make artificial sand in places without water. As it can be made dry, it doesn’t cause mud powder in the sand and gravel, so it doesn’t have to be cleaned, saving a lot of money and moving forward.

Sand making machine With Dura Mortar

Dura Mortar comes in a variety of models to suit your crushing ratio needs. With us, you’ll get the latest technology sand making machine, improve production efficiency, and improve product quality; while reducing production and maintenance costs, and reducing maintenance time.

With the 24-hour after-sales service, you’ll never have to worry about using our sand making machine.

Having A Project! We have you covered!

"Take the first step towards a successful dry mortar plant project and contact us now for expert guidance and support!"